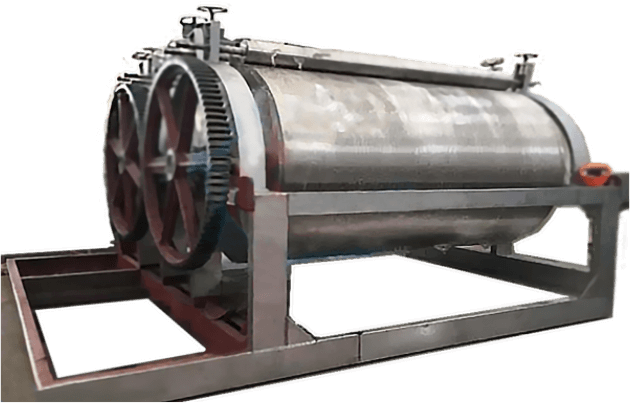

The drum flaker is a machine that helps transform a molten product into a solid form by applying cold water or ice at a solidification temperature. The crystallisation technique takes place.

The end product is the flake or needle-like solid product that goes further for packaging.

In this machine, a thin layer of molten chemical is placed on the outside surface of a rotating drum, and it is solidified by spraying cold water from inside the drum. An adjustable scraper repeatedly removes the solid paste from the drum in a flake form.

The purpose of a drum flaker and a dryer is quite the same. However, the inner surface of the drum dryer is heated with steam instead of cold water.

It further heats up the drum and removes excess moisture from the molten chemical, which, after scraping, results in a dried powdery form. Get compact and versatile flaker or dryer from the leading drum flaker manufacturer.

The Construction Details of This Drum Flaker

There are various components present inside the drum flaker machine. The units include-

Drum

The drum is made up of the best material. It can be mild or stainless steel with or without the hard chrome plating. The surface of the drum is machined and grounded. The drums rotate on an anti-friction self-aligning ball that converts the liquid to flakes.

Scrapper

The scraper knife scrapes off the flakes from the surface of the drum. It is designed to ensure a uniform pressure against the drum over the full length. The adjustment screw controls the pressure of the knife.

Hood

The flaker has an enclosed hood with vapour outlets on top.

The Advantages of Using the Drum Flaker

- High Heat Efficiency – The drum flakers are efficient in their approach. The heat efficiency is more than 90% inside these machines.

- Has Short Drying Time– drying takes only 10-15 seconds. This dryer is used to dry any heat-sensitive material.

- Provide Uniform Drying—the heat transfer is uniform throughout the drum surface, so the wet material is spread uniformly.

- Long life Span- The rotary drum is electro-polished to increase smoothness and hardness.

- Compact Size- The drying chamber is very compact and needs less space.

The drum flaker is used in various applications like extracting fatty acids, caustic acids, organic resins, caustic soda, sodium sulphide, phenolic resin, nickel catalyst, etc.

At Gem Drytech Systems LLP, you will get a drum flaker to convert liquid to solid flakes. Contact us to learn more.